Asphalt Repair Mix

In stock

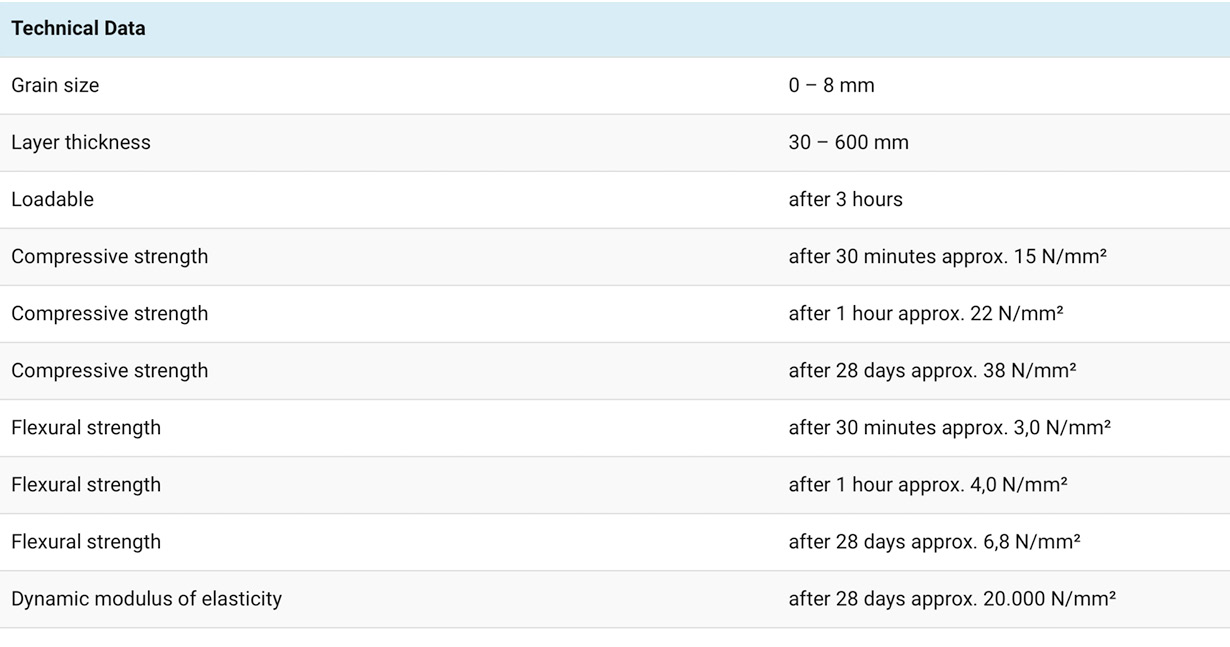

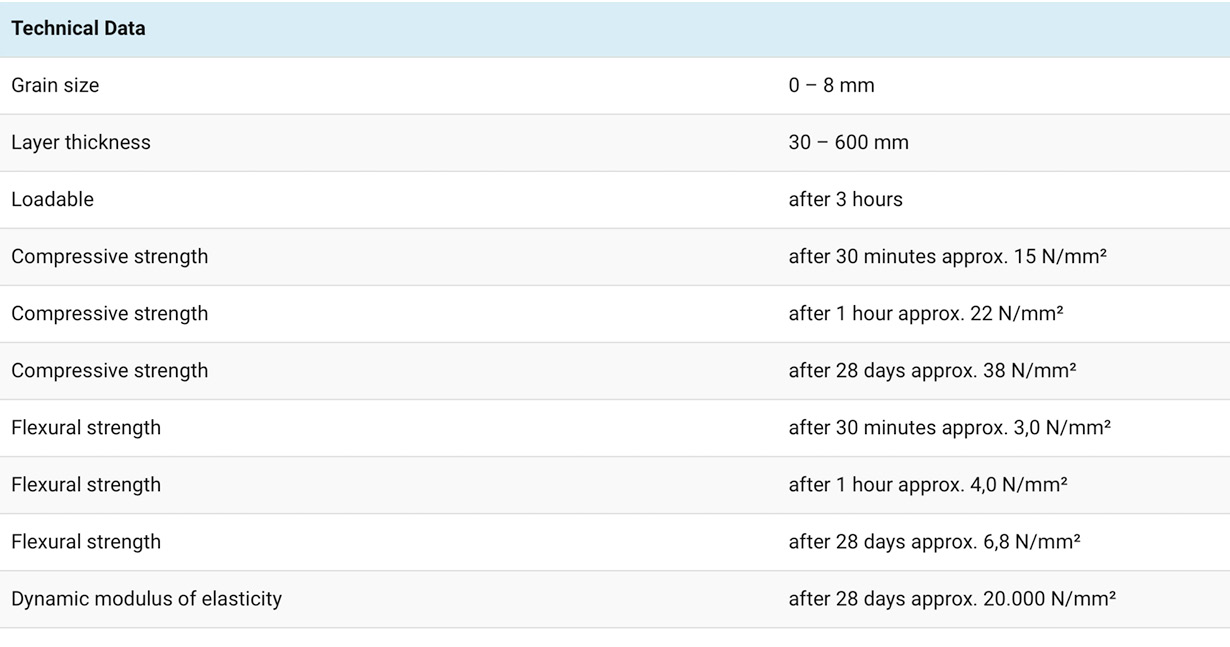

ASPHALT REPAIR MIX is a fast-setting, polymer-modified, ready to use asphalt repair material based on special cement technology.

Ideal for fast, easy and durable repair of potholes in asphalt. For the repair of road damage, frost heave, property and garage entrances, car parks, footpaths, industrial traffic areas or also for surrounds/adjustments of road sewer manholes whereby roads closures can be kept short – reopening to traffic after approx. 30 minutes only.

ASPHALT REPAIR MIX is coloured black and provides excellent adhesion without primer.

The innovative solution for easy, fast and durable asphalt repairs.

ASPHALT REPAIR MIX is a fast-setting, polymer-modified, ready to use asphalt repair material based on special cement technology.

Ideal for fast, easy and durable repair of potholes in asphalt. For the repair of road damage, frost heave, property and garage entrances, car parks, footpaths, industrial traffic areas or also for surrounds/adjustments of road sewer manholes whereby roads closures can be kept short – reopening to traffic after approx. 3 hours only.

ASPHALT REPAIR MIX is coloured black and provides excellent adhesion without primer.

Processing

Sub-base

Clean substrate with wire brush, remove loose components and dust with suitable broom. The application surface must be clean, solid and free from materials that may affect adhesion. For maximum bond, it is recommended to clean the surface thoroughly with a high-pressure washer. Remove any standing water.

For full depth repairs, remove damaged asphalt and loose debris and cut vertical sides rectangular. Saturate the surface with water before applying ASPHALT REPAIR MIX.

Mixing

Before starting work, make sure that all personal and equipment/tools required are in place. Mix ASPHALT REPAIR MIX with the specified quantity of water for approx. 1 - 3 minutes in suitable pan type mixer until a lump-free and uniform consistency is achieved. To mix, first add water into the mixing container. Then, whilst the mixer/stirrer is running, add ASPHALT REPAIR MIX. Use less water to achieve higher strength. Do NOT exceed the maximum water admixture.

Processing

ASPHALT REPAIR MIX may be processed in traditional methods. Carry out application and compaction quickly in order to allow maximum finishing time. ASPHALT REPAIR MIX may be smoothed, floated or textured, e.g. using textured roll. Apply ASPHALT REPAIR MIX in one complete layer, i.e. not in several layers, and as uniformly as possible. Do not apply on frozen

sub-base. When compacting, avoid the entry of air voids. Temperature > 20 °C will reduce the working time, temperature < 20 °C may delay the strength development.

ASPHALT REPAIR MIX may be processed at temperature between 5°C to 30°C.

Curing

After-treatment is generally not necessary. In case of high temperatures and prolonged exposure to sunlight, we recommend after-treatment with a paraffin-containing curing agent.

Supply

25 kg special paper packaging.

Storage

Dry, like cement. Shelf-life approx. 12 months.