Cement All 5kg

In stock

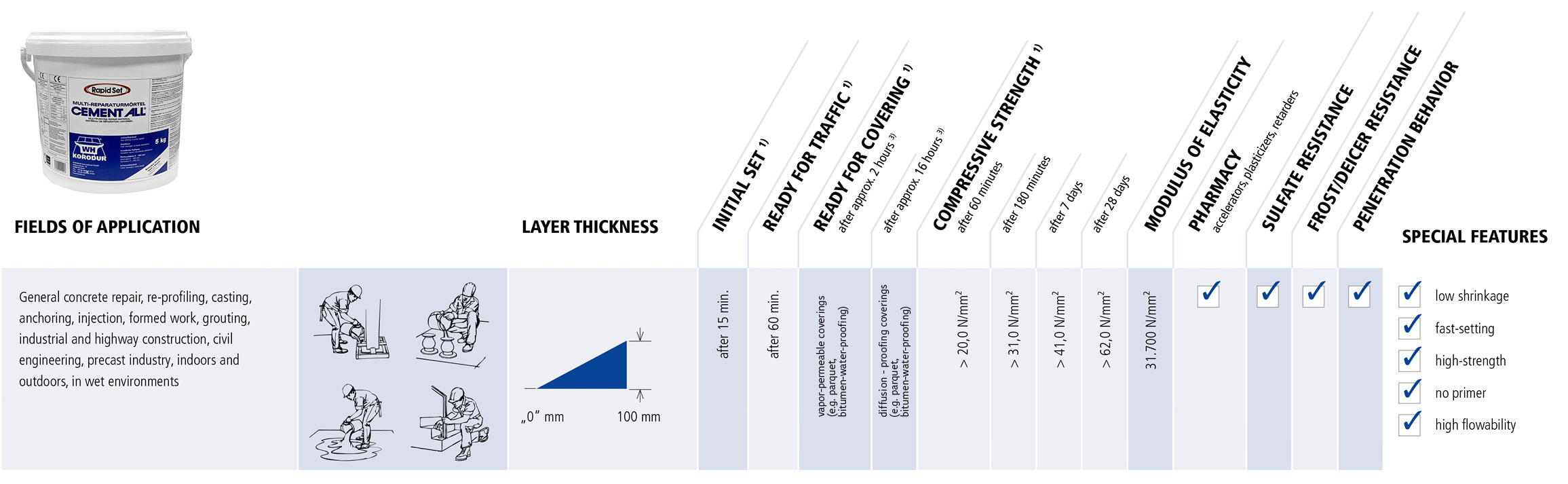

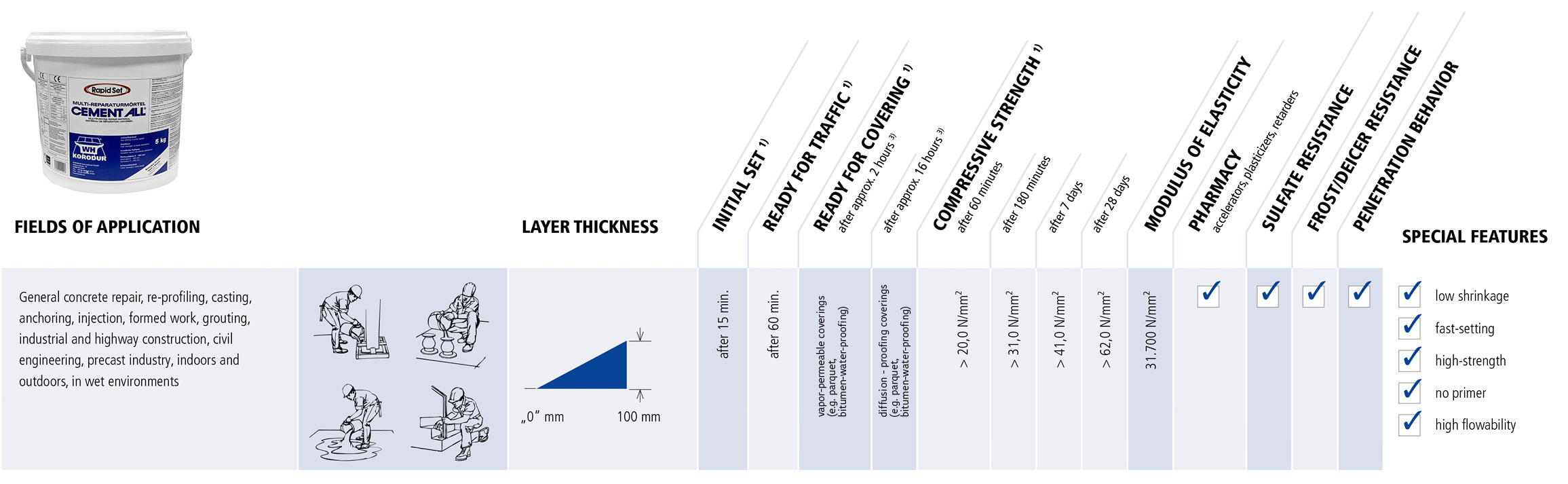

CEMENT ALL is a multipurpose product that can be used for general concrete repair, doweling and anchoring, industrial grouting, injection, formed work, airport projects, and highway repair.

Rapid Set CEMENT ALL is a high performance blend of Rapid Set Cement and specialty mineral aggregates. CEMENT ALL is non-metallic and no chlorides are added. Rapid Set CEMENT ALL is similar in appearance to portland cement repair materials and may be applied using similar methods.![]() Scroll down to learn more.

Scroll down to learn more.

Rapid Set CEMENT ALL is a mineral, multipurpose fast setting repair mortar based on special cement technology. Ideal where reapid strength, durability and low shrinkage setting is required. CEMEN ALL can be applied in thickness from nearly "0" -100mm. Initial set after 15 minutes, ready for stress in approx 1 hour. CEMENT ALL is similar in apperance to Portland cement construction materials and may be processed in similar methods.

Multipurpose Repair Mortar – high-strength, multipurpose, unique

Concrete repair with CEMENT ALL when mixed with water produces a workable, high quality repair material that is ideal where rapid strength gain, high durability and low shrinkage are desired. Apply CEMENT ALL in thickness from 0 – 100 mm. Durable in wet environments.

SETS IN 15 MINUTES & IS READY FOR TRAFFIC IN 1-HOUR.

Application

CEMENT ALL is a multipurpose product that can be used for general concrete repair, doweling and anchoring, industrial grouting, injection, formed work, airport projects, and highway repair. Rapid Set CEMENT ALL is a high performance blend of Rapid Set Cement and specialty mineral aggregates. CEMENT ALL is non-metallic and no chlorides are added. Rapid Set CEMENT ALL is similar in appearance to portland cement repair materials and may be applied using similar methods.

Properties

• Multipurpose

• Repair and new construction

• Horizonatal and vertical application

• Layer thickness "0" - 100mm

• Fast setting, ready for stress only approx 1 hour after final set

• High-strength - low tension

• Frost/de-icer resistant

• Sulfate resistant

• Chloride-free

• Resistant againt many chemical attacks

• Excellent bond: directly, without bonding compound

• Curing with water only

• Indoors and outdoors

• Improved shelf-life

Supply

5kg plastic container

25 kg special paper packaging

Storage

Dry, like cement. Shelf-life approx. 12 months.

Processing

Sub Base Clean sub-base from loose debris, cement slurry, dust acids, oils, greases. For full bond, the surface must be free from cracks, even, rough and open-pore. The surface bond strength required in the technical guidelines have to be observed (the value must not be less than 1,0N/mm2). Before the application, pre-wet the sub-base thoroughly. In case of highly absorbent sub-base, the pre-wetting may have to be repeated several times. The formation of a water film or puddles has to be avoided.

Before starting work, make sure that all personnel and equipment/tools required are in place. Mix CEMENT ALL with the specified ammount of water depending on processing method and mix for approx. 1 - 3 minutes in suitable pan type mixer or use stirrer. To mix, first add water into the filling container. Then, whilst the mixer/stirrer is running, add CEMENT ALL. Use less water to achieve higher methods. The final finish should take place as soon as possible. CEMENT ALL may be trowelled, floated or textured. Apply in one complete layer, i.e. not in several layers and as uniformly as possible. Do not apply on frozen sub-base. When compacting, avoid the entry of air voids. Temperature > 20° C will reduce the working time, temperature < 20° C may delay the strength development. To extend working time, add Rapid Set SET Control (retarder). To increase flowability, add Rapid Set FLOW Control (plasticizer) and the additive FAST to accelerate the setting time (see data sheet CONCRETE PHARMACY).