Ecotard Top Face Retarder 25ltr

In stock

Eco Surface Retarder is a light brown aqueous solution of penetrating and retarding agents acting as a top face retarder. It has been formulated to retard but not kill the set of freshly placed top face concrete that it comes into contact with.

Suitable for either sprayer watering can application. It retards the set of the surface cement matrix of freshly cast concrete for easy removal.

Benefits

- Stain Free suitable for white and standard OPC

- Enivronmentally and user Friendly

- Alleviates need for labour intensive hacking

- Contact with reinforcement will not prevent bond to concrete

- Used to create exposed aggregate finish for decorative or 'keying in' work

Application

Apply uniformly by low pressure spray or fine spray watering can in temperatures above freezing to top face of freshly placed concrete immediately after completion of placing and compaction. An excess of surface water due to bleeding of an over-wet mix will hinder penetration of retarder, therefore any excess water should be removed before treatment. After treatment protect from exposure to wind or early applied heat as this may evaporate the retarder carrier before it has sufficiently penetrated the concrete surface. Any absorbent material covering the concrete, such as hessian, should not come into contact with the Safetard Liquid as this will soak up the retarder preventing penetration into the concrete surface. On thick sections and in warmer temperatures a second application should be made on the same working day.

Coverage

A coverage of approximately 3-5 m2 per litre will generally be sufficient but in instances where the concrete mix is very dry and the material is immediately absorbed a heavier coating will be required so that a light residue remains on the surface.

Removal of retarded matrix

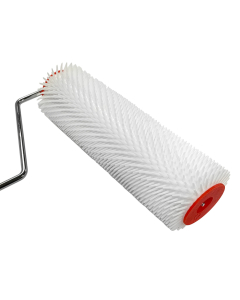

Remove by low pressure water jetting and/or brooming or wire brushing in two directions at right angles to each other. Under general conditions this should be done early on the day after placing but if this is not possible a further application should be made at the recommended rate as soon as possible on the day after placing.

Storage

Protect from Frost but if the material should freeze in the container then lightly agitate the container after thawing to ensure thorough remixing.